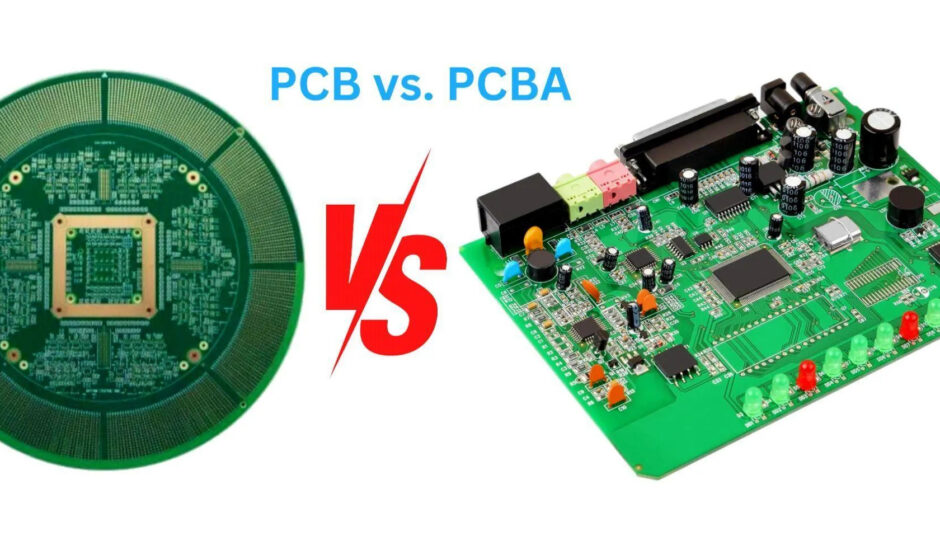

In the world of electronics, it is important for anyone involved in the manufacture or use of electronic devices to know the difference between a PCB and a PCBA. These terms sound similar, but refer to different stages in the life cycle of an electronic component. This article explains the basic differences between a PCB (Printed Circuit Board) and a PCBA (Printed Circuit Board Assembly) focusing on their function, design and importance in electronics

What is a PCB?

A PCB (printed circuit board) is a thin, rigid board made of an insulating material, usually glass, with electrical circuits printed or engraved on its surface These circuits, called traces, touch the surface of the board types together. PCBs are an integral part of modern electronics, and are the design structure for most electronic devices.

Types of PCBs

- Single-Sided PCB: Consists of a single layer of conductive material.

- Double-sided PCB: Has conductive layers on both sides.

- Multilayer PCB: Contains multiple layers of conductive material for more complex applications.

Use of PCB

PCBs are used in many areas, from devices such as phones and laptops to industrial devices and medical devices. It is essential for modern technology because of its efficiency and versatility.

What is PCBA?

A PCBA (Printed Circuit Board Assembly) is a PCB assembled with electronic components. This process converts simple PCBs into functional assemblies ready for use in devices.

PCBA process

The assembly process includes the following steps:

- Application of Solder Paste: Solder paste is applied to the PCB using a stencil for precision.

- Component placement: Machines place components such as resistors, capacitors and chips on the board.

- Soldering: Components are connected to the board using methods such as reflow or wave soldering.

- Inspection and testing: The board is tested for proper operation.

Uses of PCBA

Almost all electronic components use PCBAs, from simple devices like calculators to complex systems like airplanes.

Importance of PCB and PCBA in Electronics Industry

Both PCBs and PCBAs are important for electronics manufacturing. The PCB is the base, and the PCBA is the complete, functional one. Together, they form the core of modern electronics, helping to fit more into a smaller space more efficiently.

Contribution of top PCB manufacturers in India

Top PCB manufacturers in India also play an important role by providing quality PCBs. These workers ensure the integrity and durability of the PCB, contributing to the success of the assembly.

Choosing the right partner for PCB and PCBA

Choosing the right partners for PCBs and PCBAs is very important at the beginning of an electronics project. Keep these points in mind:

- Quality: Make sure the manufacturer or assembler follows industry standards.

- Experience: Look for proven companies.

- Cost: Balance quality and affordability.

- Support: Choose partners who will provide full support from planning to delivery.

Conclusion

Understanding the difference between a PCB and a PCBA is key to working in electronics. The PCB provides support, while the PCBA includes functions. India’s top electronics component distributors and India’s top PCB manufacturers ensure reliable and quality electronic products. By choosing the right partners and learning these strategies, companies can win in the competitive electronics market.