Prologue to Custom Machined Parts

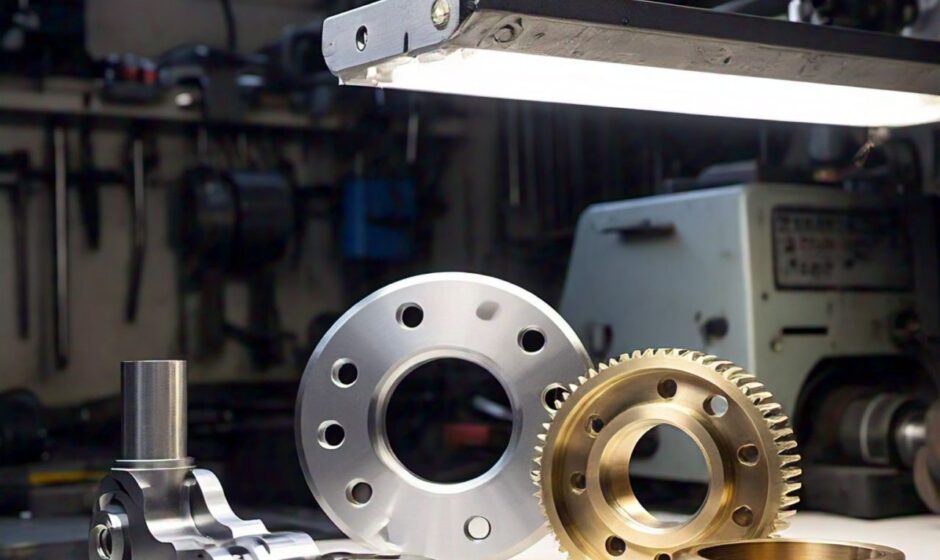

Custom machined parts are fundamental parts that take care of the different requirements of present day businesses. These parts are produced utilizing specific machining processes that consider accuracy, unwavering quality, and versatility. Not at all like standard parts, Custom machined parts are intended to meet explicit necessities, guaranteeing they line up with precise resistances, one of a kind calculations, and material details.

From aviation to clinical innovation, these parts assume a significant part in ventures where accuracy and solidness are non-debatable. Whether it’s an oddball model or large scale manufacturing of complicated parts, custom machining overcomes any issues among idea and usefulness. How about we investigate the cycles, materials, advantages, and applications that make Custom machined parts irreplaceable in the present assembling scene.

Understanding Machining Cycles

What is machining?

Machining is a subtractive assembling process that shapes natural substances into exact parts by eliminating overabundance material. The interaction utilizes cutting apparatuses, drills, or processors to accomplish the ideal plan. It is eCustom esteemed for making parts with complex subtleties and tight resistances, making it ideal for particular ventures like aviation, car, and clinical innovation.

Key kinds of machining processes

A few machining techniques are utilized in custom assembling:

Turning: This includes pivoting the workpiece on a machine while a cutting device eliminates material, usually utilized for round and hollow shapes like shafts and shafts.

Processing: A flexible cycle where a turning cutting device makes complex plans, spaces, or forms in the material.

Boring: Fundamental for making openings in exact sizes and profundities. It’s not unexpected the beginning stage for more unpredictable machining.

Crushing: This cycle smoothens surfaces and guarantees exact aspects for a great completion, ordinarily utilized in applications requesting flawlessness.

Every one of these cycles can be custom-made to make uniquely machined parts, guaranteeing that each part meets careful details.

Advantages of Custom Machined Parts

Accuracy and exactness

One of the greatest benefits of Custom machined parts is their accuracy. With resistances as low as a couple of micrometers, these parts ensure an ideal fit, limiting blunders during gathering or activity.

Material adaptability

Custom machining upholds various materials, from lightweight metals like aluminum to rock solid composites like titanium. This adaptability guarantees that makers can pick the right material in view of solidarity, weight, or consumption opposition prerequisites.

Solidness and unwavering quality

By utilizing high-grade materials and following severe machining processes, custom parts are worked to endure unforgiving circumstances, guaranteeing long haul execution.

Cost-adequacy

While the forthright expense of custom machining could appear to be high, it decreases long haul costs by dispensing with the requirement for regular fixes, overhauls, or substitutions.

Ventures Depending on Custom Machined Parts

Custom machined parts are indispensable across different ventures. The following are a couple of eminent models:

Airplane business: Accuracy parts like turbine sharp edges, landing gear parts, and primary sections are fundamental for airplane wellbeing and execution.

Car area: Motor parts, transmission parts, and stopping mechanisms depend on custom machining for ideal usefulness.

Clinical innovation: From careful instruments to prosthetics and dental inserts, machining guarantees accuracy and dependability in medical services.

Gadgets and innovation: Elite execution gadgets, including semiconductors and connectors, rely upon custom machining for scaled down yet practical parts.

Materials Utilized for Custom Machined Parts

Metals

Metals are the foundation of Custom Industrial Manufacturing Services machined parts because of their solidarity, strength, and flexibility:

Aluminum: Lightweight and consumption safe, aluminum is great for auto and aviation applications.

Hardened steel: Known for its solidarity and protection from wear, treated steel is broadly utilized in clinical and modern gear.

Titanium: Titanium joins strength with daintiness, making it priceless in aviation and clinical inserts.

Plastics

Machined plastics give adaptability and compound protection from explicit businesses:

ABS: Normally utilized in models and hardware, ABS offers toughness and moderateness.

Look: This elite presentation plastic is generally utilized in clinical and aviation applications because of its superb warm and substance obstruction.

Nylon: Nylon’s adaptability and effect opposition make it appropriate for gears and other mechanical parts.

The Job of computer aided design and CAM in Custom Machining

Computer aided design (PC Supported Plan)

Computer aided design programming permits architects to make exact advanced models of custom parts. These 3D models act as an outline for the machining system, guaranteeing everything about with determinations.

CAM (PC Supported Assembling)

CAM programming makes an interpretation of computer aided design models into machine-intelligible guidelines, directing CNC machines to execute the plan with accuracy.

Advantages of computer aided design and CAM combination

The blend of computer aided design and CAM smoothes out the creation cycle, diminishes mistakes, and guarantees that parts are fabricated to correct resiliences. This is eCustom basic for ventures like aviation and medical services, where accuracy is principal.

Picking the Ideal Maker for Uniquely Machined Parts

Choosing the perfect producer is pivotal to guaranteeing excellent parts:

Experience and skill: Search for makers with a demonstrated history in your industry.

Accreditations: Guarantee the maker follows industry principles, for example, ISO 9001 or AS9100.

Abilities: Confirm that they can deal with the expected materials, resistances, and creation volumes.

Quality control: A dependable maker ought to have powerful review cycles to ensure steady quality.

Difficulties in Custom Machining

Custom machining isn’t without its difficulties:

Complex plans: Parts with complicated calculations require progressed devices and aptitude.

Material constraints: Certain materials are more earnestly to machine, which can influence lead times and expenses.

Tight resistances: Accomplishing very exact aspects frequently requires extra machining time and assets.

Procedures to conquer difficulties

Working with experienced makers and putting resources into cutting edge apparatus can assist with alleviating these difficulties. Also, clear correspondence among architects and mechanical engineers guarantees smooth creation.

Future Patterns in Uniquely Machined Parts

As innovation propels, custom machining keeps on advancing:

Artificial intelligence and robotization: Computerized reasoning is being incorporated into machining processes, further developing proficiency and exactness.

Green assembling: Eco-accommodating practices, like utilizing reused materials and diminishing waste, are building up some decent momentum.

Ultra-accuracy machining: Advancements are empowering producers to accomplish resistances at the nanoscale, opening ways to new applications.

Conclusion

Custom machined parts are fundamental for ventures that request accuracy, sturdiness, and flexibility. From aviation to clinical gadgets, these parts are intended to meet careful details, guaranteeing ideal execution in even the most difficult conditions. The joining of trend setting innovations like computer aided design/CAM and CNC precision machining has reformed the assembling system, making it more productive and dependable than any time in recent memory.

As ventures keep on developing, the interest for uniquely machined parts will just develop. Whether it’s prototyping an earth shattering plan or delivering elite execution parts at scale, custom machining stays a foundation of current assembling.

FAQs

1. What is the distinction among standard and uniquely machined parts?

Standard parts are pre-planned and efficiently manufactured, while Custom machined parts are custom-made to meet explicit necessities, including novel aspects, materials, and resiliences.

2. How might I guarantee the nature of Custom machined parts?

To guarantee quality, work with confirmed producers who follow severe quality control conventions. Demand point by point assessment reports and confirm consistence with industry norms.

3. What is the run of the mill lead time for custom machining?

Lead times change in light of the intricacy of the plan, materials utilized, and creation volume. By and large, it can take anyplace from a couple of days to a little while.

4. Which enterprises benefit most from Custom machined parts?

Ventures like aviation, auto, clinical innovation, and gadgets intensely depend on uniquely machined parts for their accuracy and strength.

5. Are Custom machined parts financially savvy for little requests?

While the forthright expense might be higher for little orders, the accuracy and sturdiness of uniquely machined parts frequently legitimize the cost, particularly for specific applications.