Global Blowout Preventer Market Outlook

The global market for blowout preventers (BOP) is poised for steady growth, with a projected compound annual growth rate (CAGR) of approximately 3.70% during the forecast period of 2024-2032. This growth is primarily driven by the increasing subsea drilling activities, which are critical to meeting the rising global demand for oil and gas. As offshore exploration and production operations expand into deeper and more challenging environments, the need for reliable blowout preventers becomes even more crucial. This article explores the key factors driving the blowout preventer market, emerging trends, challenges, and the future outlook for this essential sector.

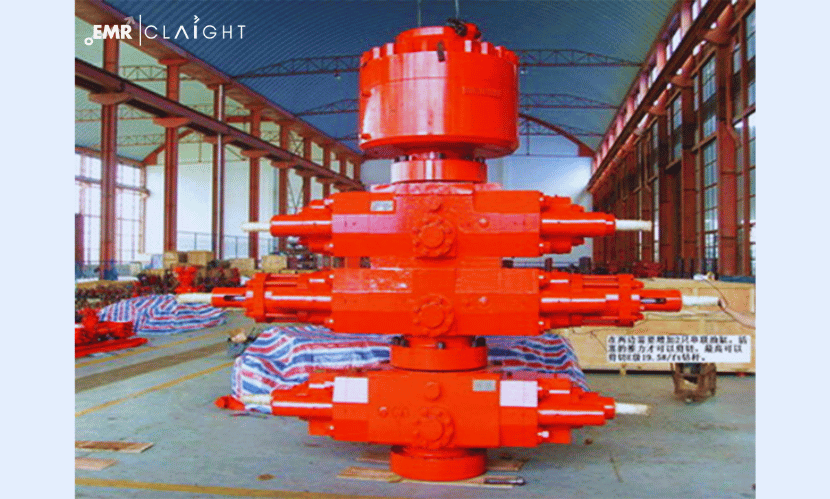

Understanding Blowout Preventers

Blowout preventers are critical safety devices used in the oil and gas industry to prevent the uncontrolled release of crude oil or natural gas from a well during drilling operations. These devices are designed to seal, control, and monitor the wellbore to prevent blowouts, which can have catastrophic environmental and economic consequences. Blowout preventers are typically installed at the wellhead and can be activated automatically or manually in response to abnormal pressure conditions.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/blowout-preventer-market/requestsample

There are two main types of blowout preventers: annular BOPs and ram BOPs. Annular BOPs use a rubber sealing element to close around the drill pipe, while ram BOPs use steel rams to seal the wellbore. In many cases, both types of BOPs are used in combination to provide multiple layers of protection.

Key Factors Driving Market Growth

1. Increasing Subsea Drilling Activities

One of the primary drivers of the global blowout preventer market is the increasing subsea drilling activities. As onshore oil and gas reserves become increasingly depleted, energy companies are turning to offshore and subsea reserves to meet the growing global demand for hydrocarbons. Subsea drilling presents unique challenges, including high pressure and temperature conditions, which require advanced safety equipment such as blowout preventers.

The exploration and production of oil and gas in deepwater and ultra-deepwater environments have been on the rise, particularly in regions such as the Gulf of Mexico, the North Sea, and offshore Brazil. These operations require robust and reliable blowout preventers to ensure the safety of drilling personnel and the environment. As a result, the demand for BOPs designed for subsea applications is expected to increase, driving the growth of the market.

2. Stringent Safety Regulations

The oil and gas industry is subject to stringent safety regulations aimed at preventing blowouts and minimizing the environmental impact of drilling operations. Regulatory bodies in key oil-producing regions, such as the Bureau of Safety and Environmental Enforcement (BSEE) in the United States, have implemented strict standards for the design, maintenance, and operation of blowout preventers.

Following high-profile incidents such as the Deepwater Horizon blowout in 2010, regulatory scrutiny has intensified, leading to more rigorous testing and certification requirements for BOPs. Manufacturers of blowout preventers must ensure that their products meet these stringent standards to remain competitive in the market. The need for compliance with safety regulations is expected to drive demand for high-quality blowout preventers, contributing to market growth.

Explore the full report with the table of contents@ https://www.expertmarketresearch.com/reports/blowout-preventer-market

3. Technological Advancements in BOP Design

Technological advancements in blowout preventer design are playing a crucial role in driving market growth. Innovations in materials, control systems, and monitoring technologies have led to the development of more reliable and efficient BOPs. For example, the integration of real-time monitoring and diagnostic systems allows operators to detect potential issues early and take corrective action before a blowout occurs.

Advances in metallurgy and materials science have also improved the durability and performance of blowout preventers, enabling them to withstand the extreme pressures and temperatures encountered in deepwater drilling. Additionally, the development of automated and remotely operated BOP systems has enhanced the safety and efficiency of drilling operations, reducing the risk of human error.

As the oil and gas industry continues to explore new frontiers, such as the Arctic and other remote regions, the demand for advanced blowout preventers with enhanced capabilities is expected to increase.

4. Growing Focus on Environmental Protection

The growing focus on environmental protection and sustainability is another key driver of the blowout preventer market. Blowouts can have devastating environmental consequences, including oil spills that can damage marine ecosystems and coastal communities. As public awareness of environmental issues increases, there is greater pressure on oil and gas companies to adopt best practices and invest in safety equipment that minimizes the risk of blowouts.

In response to these concerns, many oil and gas companies are prioritizing the use of advanced blowout preventers as part of their environmental management strategies. The adoption of environmentally friendly drilling practices, including the use of BOPs that reduce the risk of oil spills, is expected to drive market growth.

5. Expanding Offshore Exploration in Emerging Markets

The expansion of offshore exploration and production activities in emerging markets, particularly in Asia-Pacific and Africa, is expected to drive the demand for blowout preventers. Countries such as India, China, and Nigeria are investing in the development of their offshore oil and gas reserves to reduce their dependence on imported energy and support economic growth.

As these countries ramp up their offshore drilling activities, the need for reliable blowout preventers will increase. The development of new offshore fields in these regions presents significant opportunities for BOP manufacturers and suppliers, contributing to the overall growth of the market.

Emerging Trends in the Blowout Preventer Market

1. Digitalization and Remote Monitoring

Digitalization is transforming the blowout preventer market, with the integration of remote monitoring and diagnostic technologies becoming a key trend. The use of digital sensors and data analytics allows operators to monitor the performance of BOPs in real-time, providing early warning of potential issues and enabling proactive maintenance.

Remote monitoring systems can detect anomalies in pressure, temperature, and other critical parameters, allowing operators to take corrective action before a blowout occurs. This capability is particularly valuable in offshore and subsea drilling, where quick response times are essential for preventing accidents.

The adoption of digital technologies is expected to enhance the safety and reliability of blowout preventers, making them more attractive to operators in the oil and gas industry.

2. Development of Compact and Lightweight BOPs

Another emerging trend in the blowout preventer market is the development of compact and lightweight BOPs. As drilling operations move into deeper and more remote locations, there is a growing need for equipment that is easier to transport and install. Compact BOPs are designed to be more maneuverable and easier to deploy, making them well-suited for use in offshore and subsea environments.

The development of lightweight materials and innovative engineering designs has made it possible to reduce the size and weight of blowout preventers without compromising their performance. This trend is expected to drive demand for compact BOPs, particularly in regions where logistics and transportation are challenging.

3. Increasing Use of Subsea BOPs

The increasing use of subsea blowout preventers is a significant trend in the market, driven by the growth of deepwater and ultra-deepwater drilling activities. Subsea BOPs are installed on the seabed, directly above the wellhead, and are designed to withstand the extreme pressures and temperatures encountered in deepwater drilling.

Subsea BOPs offer several advantages over surface BOPs, including enhanced safety, reduced risk of blowouts, and improved operational efficiency. As offshore exploration and production activities expand into deeper waters, the demand for subsea BOPs is expected to increase, driving market growth.

4. Focus on Reducing Maintenance Costs

The focus on reducing maintenance costs is another trend shaping the blowout preventer market. Maintenance and inspection of BOPs can be costly and time-consuming, particularly in offshore environments where access to equipment is limited. To address this challenge, manufacturers are developing BOPs with longer service intervals and improved durability.

The use of advanced materials and coatings that resist corrosion and wear is helping to extend the lifespan of blowout preventers, reducing the need for frequent maintenance and repairs. Additionally, the integration of remote monitoring and predictive maintenance technologies allows operators to identify and address potential issues before they lead to equipment failure, further reducing maintenance costs.

Challenges in the Blowout Preventer Market

1. High Cost of Blowout Preventers

One of the primary challenges facing the blowout preventer market is the high cost of these devices. Blowout preventers are complex pieces of equipment that require advanced engineering and materials, making them expensive to manufacture and maintain. The high cost of BOPs can be a barrier to adoption, particularly for smaller oil and gas companies with limited budgets.

To mitigate this challenge, some companies are exploring alternative financing options, such as leasing or renting blowout preventers. Additionally, the development of cost-effective BOPs with longer service intervals and lower maintenance requirements could help reduce the overall cost of ownership, making them more accessible to a wider range of operators.

2. Regulatory Compliance and Certification

Regulatory compliance and certification are critical considerations in the blowout preventer market. BOPs must meet strict safety and performance standards set by regulatory bodies in key oil-producing regions. Compliance with these standards can be challenging, particularly for manufacturers that operate in multiple jurisdictions with different regulatory requirements.

The certification process for blowout preventers can be lengthy and expensive, requiring extensive testing and documentation. Failure to meet regulatory standards can result in costly delays, fines, and reputational damage. To address this challenge, manufacturers must invest in research and development to ensure that their products meet or exceed regulatory requirements.

3. Technical Challenges in Deepwater Drilling

Deepwater drilling presents significant technical challenges that can impact the performance of blowout preventers. The extreme pressures and temperatures encountered in deepwater environments can put significant stress on BOPs, increasing the risk of equipment failure. Additionally, the complexity of deepwater drilling operations can make it difficult to access and maintain blowout preventers.

To overcome these challenges, manufacturers are developing BOPs with enhanced durability and reliability, designed specifically for deepwater applications. The use of advanced materials, such as high-strength alloys and composites, can help improve the performance of BOPs in harsh conditions. Additionally, the integration of remote monitoring and diagnostic technologies can help operators detect and address potential issues before they lead to equipment failure.

Future Outlook for the Blowout Preventer Market

The global blowout preventer market is expected to continue its steady growth trajectory over the forecast period of 2024-2032. The projected CAGR of 3.70% reflects the ongoing demand for reliable and advanced BOPs in the oil and gas industry. Several factors will play a key role in shaping the future of the market, including advancements in technology, regulatory developments, and the expansion of offshore exploration activities.

1. Advancements in Technology

Technological advancements will be a critical driver of the blowout preventer market in the coming years. The integration of digital technologies, such as remote monitoring and predictive maintenance, will enhance the safety and reliability of BOPs, making them more attractive to operators. Additionally, the development of compact and lightweight BOPs will improve the efficiency and cost-effectiveness of drilling operations, particularly in offshore environments.

2. Regulatory Developments

Regulatory developments will continue to influence the blowout preventer market, with increasing scrutiny on safety and environmental protection. Manufacturers must stay ahead of regulatory changes and invest in research and development to ensure that their products meet or exceed safety standards. The adoption of best practices and compliance with regulations will be critical to maintaining market competitiveness.

3. Expansion of Offshore Exploration

The expansion of offshore exploration and production activities, particularly in emerging markets, will drive the demand for blowout preventers. As oil and gas companies explore new frontiers, such as deepwater and ultra-deepwater environments, the need for robust and reliable BOPs will increase. The development of new offshore fields in regions such as Asia-Pacific and Africa presents significant growth opportunities for the blowout preventer market.

Read More Reports:

https://www.expertmarketresearch.com/reports/lighting-market

https://www.expertmarketresearch.com/articles/top-labels-companies

https://www.expertmarketresearch.com/articles/top-tissues-paper-companies

Media Contact:

Company Name: Claight Corporation

Contact Person: Steven Luke, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/