Air Bearings Market Introduction

The global air bearings market reached a value of USD 7.06 billion in 2023. The market is further estimated to grow at a CAGR of 6.8% during 2024-2032 to reach a value of USD 12.79 billion by 2032. These figures underscore the significant role that air bearings are playing in various industries worldwide. From manufacturing and aerospace to medical devices and metrology, air bearings are transforming the way machines operate, offering unparalleled precision, reliability, and efficiency.

In this comprehensive guide, we’ll delve into the advantages driving the adoption of air bearings and explore how they’re revolutionizing industries across the globe.

Precision and Performance:

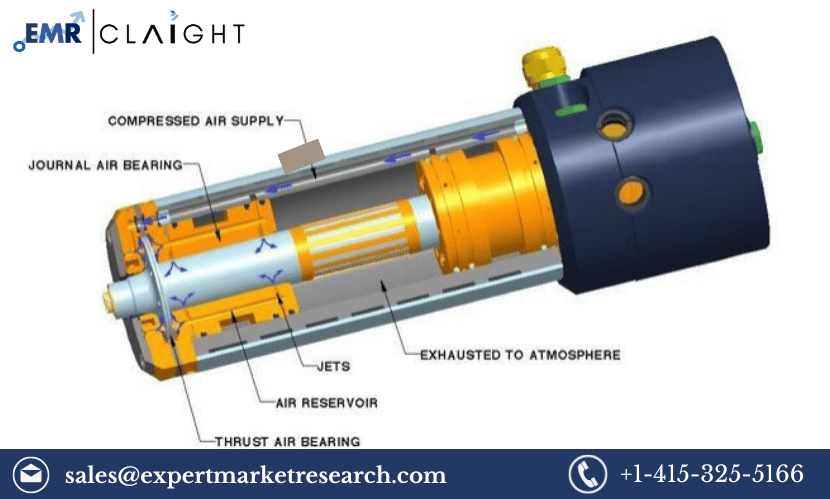

Air bearings are renowned for their ultra-high precision capabilities, enabling nanometer-level accuracy in various applications. Unlike traditional bearings, which rely on physical contact between surfaces, air bearings utilize a thin film of pressurized air to float the load, eliminating friction and allowing for smooth, precise motion. This level of precision is crucial in industries such as semiconductor manufacturing, where even the slightest deviation can result in costly defects.

Furthermore, air bearings facilitate high-speed operation, thanks to their low friction design. By minimizing resistance, air bearings enable machines to operate at speeds that would be unattainable with conventional bearings. This capability is particularly beneficial in fields like machine tools and aerospace, where efficiency and speed are paramount.

Get a Free Sample Report with Table of Contents@ https://www.expertmarketresearch.com/reports/air-bearings-market/requestsample

Maintenance and Reliability:

One of the key advantages of air bearings is their reduced maintenance requirements compared to traditional bearing systems. Since air bearings operate without physical contact between surfaces, there’s no need for lubrication or regular maintenance to prevent wear and tear. This not only saves time and resources but also minimizes the risk of equipment failure and downtime.

Moreover, air bearings are known for their longevity and durability. Unlike traditional bearings, which can degrade over time due to friction and wear, air bearings can last significantly longer, resulting in lower replacement costs and greater operational reliability. Industries such as medical devices and high-precision machinery benefit greatly from the extended lifespan of air bearings, ensuring consistent performance and minimal downtime.

Cleanliness and Environmental Impact:

In addition to their precision and reliability, air bearings offer advantages in terms of cleanliness and environmental impact. Because they operate without physical contact, air bearings prevent contamination and particulate generation, making them ideal for applications that require a clean and sterile environment. This is particularly important in industries such as semiconductor manufacturing and cleanroom operations, where even minor contaminants can compromise product quality.

Furthermore, air bearings contribute to sustainability efforts by reducing energy consumption and environmental impact. Unlike traditional lubricated bearings, which require constant replenishment of lubricants and generate waste, air bearings operate efficiently without the need for lubrication, resulting in lower energy consumption and reduced carbon emissions.

Future Outlook:

The future outlook for air bearings is promising, with continued advancements in technology and expanding applications across diverse industries. As the global demand for precision, efficiency, and sustainability grows, air bearings are poised to play an increasingly vital role in meeting these evolving needs.

Technological Advancements:

The ongoing research and development in air bearings technology are expected to lead to further innovations and improvements. Advancements in materials science, design optimization, and manufacturing techniques will likely result in air bearings that offer even higher precision, reliability, and efficiency. Emerging technologies such as additive manufacturing may also revolutionize the production process, allowing for more complex and customized air bearing designs.

Diversification of Applications:

While air bearings have already found success in industries such as semiconductor manufacturing, aerospace, and metrology, their adoption is expected to expand into new sectors. Industries ranging from medical devices and robotics to renewable energy and automotive manufacturing are likely to embrace air bearings for their precision motion control and reliability. As new applications emerge, the demand for specialized air bearing solutions tailored to specific requirements will increase.

Integration with Industry 4.0:

The rise of Industry 4.0, characterized by the integration of digital technologies and automation in manufacturing processes, presents new opportunities for air bearings. Air bearings can seamlessly integrate with advanced control systems, IoT devices, and machine learning algorithms to enable real-time monitoring, predictive maintenance, and adaptive control. This integration will enhance operational efficiency, reduce downtime, and unlock new possibilities for optimization and innovation.

Sustainability and Environmental Impact:

As environmental concerns become increasingly prominent, the sustainability benefits of air bearings will drive their adoption further. With their frictionless operation and reduced maintenance requirements, air bearings contribute to energy conservation and minimize environmental impact. Manufacturers across industries will prioritize sustainable solutions, making air bearings an attractive choice for achieving efficiency goals while reducing carbon footprint.

Global Market Growth:

The projected growth of the global air bearings market indicates a robust demand for these technologies in the coming years. Factors such as industrial automation, precision engineering, and technological advancements in emerging economies will fuel market expansion. Additionally, the growing emphasis on quality control, miniaturization, and high-speed manufacturing will drive the adoption of air bearings across diverse sectors, propelling market growth worldwide.

Media Contact:

Company Name: Claight Corporation

Contact Person: Louis Wane, Corporate Sales Specialist – U.S.A.

Email: sales@expertmarketresearch.com

Toll Free Number: +1-415-325-5166 | +44-702-402-5790

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Website: https://www.expertmarketresearch.com

Aus Site: https://www.expertmarketresearch.com.au/